ITO Glass Substrates, 20 x 15 mm, OFET and Sensing

Materials, Substrates and FabricationSpecifications | Literature and Reviews

The Ossila pre-patterned ITO OFET and sensing substrates have been designed to enable the fabrication and characterisation of transistors and sensing devices without the need for vacuum evaporations or probe stations. This allows devices to be produced and tested with significantly increased simplicity, making the system ideal for reducing costs of material screening experiments; as well as teaching and training purposes.

Specifications

| Substrate Size | 20 mm x 15 mm |

|---|---|

| Pack Size | 100 substrates per standard pack |

| Thickness | 1.1 mm |

| Channel Dimensions* |

S161: W × L: 30 mm × 50 μm S162: W × L: 30 mm × 50 μm, 75 μm, 100 μm, 150 μm and 200 μm |

| Glass Type | Polished soda lime, float glass |

| Substrate Coating | Fully oxidized ITO |

| ITO Thickness | 100 nm |

| ITO Resistance | 20 Ω / square |

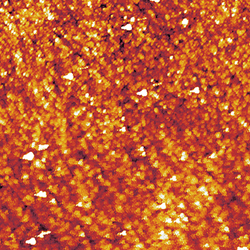

| Glass Roughness | <1 nm RMS (By AFM) |

| ITO Roughness | 1.8 nm RMS (By AFM) |

*There may be a batch-to-batch variation of ±10 μm in the channel length

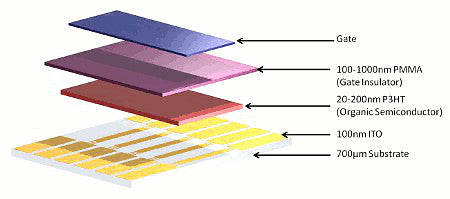

The exploded diagram below illustrates the layers typically used with the evaporation-free OFET substrates. The substrates contain pre-patterned ITO source-drain contacts onto which the semiconductor is deposited before a gate insulator is spun on top and finally the gate material finishes the device. All of these layers can be deposited from solution, meaning no evaporation shadow masks are required. However, we stock active area masks, gate masks and gate insulator masks, for when vacuum deposition is required.

The pre-patterned OFET substrates consist of interdigitated ITO fingers to act as the source-drain electrodes, and have overall channel dimensions of 30 mm x 50 μm. These relatively large channels work to minimize contact effects, so it is less important to match the energy levels of the organic semiconductor and contacts. As such, the intrinsic Poole Frenkel limited mobility of a material can be more easily assessed independent of the HOMO level. The 30 mm channel width also has the additional benefit of producing larger currents, making testing and measurement quicker and requiring less sensitive (and less expensive) equipment.

The substrate itself is made of high-quality soda-lime float glass with a 20 nm coating of SiO2 (synthetic quartz). The transparent nature of the ITO/glass also means that opto-electric experiments can be done with ease (photoconductivity, photo-induced doping in the presence of oxygen, sensing).

Transistors can be fabricated by simply depositing an organic semiconductor, gate insulator and gate on the substrates (see diagram below for device schematic). By using a synthetic metal (such as PEDOT:PSS) deposited from solution for the gate, it is possible to make fully-functioning OFETs by solution processing alone, eliminating vacuum evaporation processes. The use of the Ossila OFET test board also means that devices can be measured at the flick of a switch without the need for probe stations.

While all solution-based processing allows transistors to be fabricated in a matter of minutes, the substrates are also designed to work with a wide variety of different material systems and deposition techniques. As such, vacuum-deposited semiconductors, gate insulators and gates can also be used with the appropriate shadow mask.

Transmittance of ITO Substrates

Literature and Reviews

- Molecular weight dependent vertical composition profiles of PCDTBT:PC71BM blends for organic photovoltaics, J. K. Kingsley et al., Scientific Reports 4, 5286 (2014).

- Medium band gap polymer based solution-processed high-κ composite gate dielectrics for ambipolar OFET, B. Canımkurbey et al., J. Phys. D: Appl. Phys., 51, 125104 (2018).