Hexagonal Boron Nitride Properties

The properties of bulk hexagonal boron nitride crystals differ from that of the monolayer material. The bulk exists as layered hexagonal lattice material similar to graphite.

Hexagonal boron nitride (h-BN) has a variety of properties associated with its bulk layered and 2D monolayer forms. Bulk h-BN consists of multiple layers held together by van der Waals forces, affecting its electrical, optical, and thermal properties. It generally behaves as an insulator with good thermal conductivity along the planes. In contrast, monolayer h-BN, comprising a single layer of boron and nitrogen atoms, exhibits distinct properties such as a larger band gap and enhanced mechanical strength and thermal conductivity. This makes it ideal for applications requiring thin, transparent, and thermally efficient materials.

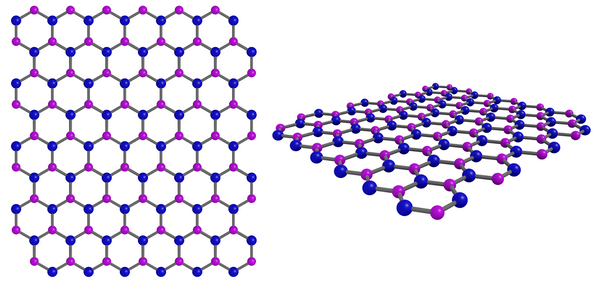

The hexagonal lattice structure of boron and nitrogen contains strong in-plane polar covalent bonds. The polarity of the bonds means h-BN is anisotropic and has many unique and desirable properties.

Structure and Composition of h-BN

Low Specific Density

Hexagonal boron nitride is relatively light weight for its volume and has a density of 2.1 g/cm³. This is due to it's molecular structure. The weak inter-layer interactions mean that the hexagonal layers of h-BN are far apart compared to the atomic diameters. This increases the volume without significantly increasing the mass of the material.

Large Specific Surface Area

2D hexagonal boron nitride nanosheets exhibit large specific surface area (~2600 m2/g) especially when compared to bulk layered h-BN (< 10 m2/g). The nanosheets are atomically thick with large lateral dimensions therefore have a much larger surface area to volume ratio.

Large Inter-layer Shear Force

The bending stiffness of hexagonal boron nitride nanosheets (BNNS) with two to six layers follows a power function of their thickness, characterized by a power index of approximately 2.35. This stiffness is much higher than that of similar graphene layers. However, a single layer of graphene is stiffer than a single layer of h-BN. The higher bending stiffness in multilayer BNNS is due to its partially ionic boron-nitride bonds and a corrugated electronic structure. These factors lead to a interlayer interaction in h-BN that is ten times stronger than graphene.

Electronic Properties

Dielectric Anisotropy

Hexagonal boron nitride exhibits different dielectric responses in directions parallel to the layers (in-plane) and perpendicular to the layers (out-of-plane):

In-plane dielectric constant: ~ 4 - 5

Out-of-plane dielectric constant: ~ 3 - 4

Anisotropic (varying magnitude depending on direction of measurement)

Parallel to the h-BN layers, boron and nitrogen atoms are connected through strong polar covalent bonds. Due to the different electronegativities of boron and nitrogen there is a larger response to an external electromagnetic field. The dielectric response remains consistent regardless of the number of layers of h-BN.

Perpendicular to h-BN layers weak van der Waals (vdWs) interactions dominate. This results in lower polarizability as vdWs forces are less effected by an external electromagnetic field. Therefore there is a lower dielectric constant compared to the in-plane direction. The out-of-plane dielectric constant increases slightly as more h-BN layers are added. This is due to cumulative effect of these weaker interactions across multiple layers.

Wide Band Gap

A single layer of hexagonal boron nitride (h-BN) has a direct band gap of about 6 eV. This means electron transitions from the valence band to the conduction band can occur without momentum change. However, as h-BN layers increase to bulk form, the band gap becomes indirect—about 5.95 eV. This is similar to changes seen in materials like molybdenum disulfide, where the band energies shift to different positions in the Brillouin zone.

Learn more about the hexagonal boron nitride band gap.

Thermal Properties

Good Thermal Stability

Hexagonal boron nitride is stable up to temperatures of 800 - 900°C in air and 1400°C in vacuum (better than graphene). It has a very high melting point of ~3000 °C. This is due to the strong covalent bonds between boron and nitrogen within the h-BN layers. The partial ionic character of the covalent bonds adds electrostatic attraction to the bonding. This increases the overall energy required to break the bonds.

High Thermal Conductivity

At room temperature, the thermal conductivity of h-BN is 300-2000 W m1 K1, which is higher than the majority of metals and ceramic materials but not as good as graphene. This means it can effectively dissipate heat, reducing the risk of thermal hotspots that might degrade materials. The strong covalent bonds are good at transmitting thermal vibrations and due to the close hexagonal lattice the vibrations spread easily through the plane.

Out-of-plane thermal conductivity is much lower in h-BN. The the weak van der Waals forces do not facilitate the transfer of heat effectively.

Optical Properties

Hyperbolic Behaviour

In hexagonal boron nitride optical phonons exist as vibrations from the relative motion of δ+ boron and δ- nitrogen sublattices against each other. These phonons can interact with electromagnetic radiation in the mid-infrared to terahertz frequency ranges. When photons interact with the optical phonon they form hybrid modes called phonon polaritons.

As discussed above, the in-plane and out-of-plane dielectric constants are different for h-BN. Therefore, it can be described has having hyperbolic dispersion. This means polaritons that can propagate with very large wave vectors within the material volume, enabling ultra-high optical confinement (~1000 times smaller wavelength than that of light in free space).

The iso-frequency contour of the material is hyperbolic as opposed to being spherical or elliptical as in normal isotropic materials. This hyperbolic dispersion allows for unique electromagnetic behaviours. It supports the propagation of high-k (high wavevector) mode, which are wavevectors with large magnitudes. Polaritons exhibit low optical losses and can propagate over relatively long distances compared to other materials that support similar polaritonic modes.

Mechanical Strength

High Fracture Toughness

Hexagonal boron nitride has a high strength of ~ 100 GPa and very high elastic modulus of 0.8 TPa. These values are comparable to graphene. h-BN is significantly stiffer and more resistant to deformation under stress than many common engineering materials.

The fracture behaviour of hexagonal boron nitride was thought to be similar to that of graphene due to the similarity in strength and elastic modulus. However, single-crystal monolayer h-BN exhibits remarkably high fracture toughness. It is significantly greater than both its own predicted values and those reported for graphene. This toughness is demonstrated by the material's ability to sustain stable crack growth. The toughness is further enhanced by mechanisms such as crack deflection and branching, caused by the unique elastic properties at the crack tip and edge swapping during the crack's growth.

The branching of cracks dissipates the energy required to propagate the crack more effectively than a single, straight crack would. This energy dissipation results from the additional surface area created by multiple crack paths, which requires more energy to extend. The material can better resist fracture and delay the propagation of cracks.

Good Flexibility

The atomic thinness of monolayer hexagonal boron nitride enables bending. Its strong intra-layer bonds allow it to withstand this bending. The covalent bonds remain undistorted, allowing the entire planar structure to curve.

Low Friction

Layers of hexagonal boron nitride are held together by weak van der Waals forces. These interactions can be easily disrupted and the layers can slide over each other with little friction. As the layers of h-BN slide over each other, small flakes or plates of the material can be transferred to the sliding surfaces, forming a lubricating layer. This transfer film acts to separate the sliding surfaces, reducing direct contact and minimizing wear.

Chemical Resistance

Ultrathin hexagonal boron nitride films are considered chemically inert. The chemical resistance of h-BN starts at the atomic level, where strong covalent bonds between boron and nitrogen create a very stable lattice. Its atoms are neither prone to donating nor accepting electrons easily from other substances, which minimizes unwanted chemical reactions.

h-BN films are resistant to oxygen diffusion even at high temperatures and can serve as high-performance oxidation-resistant coatings. They exhibit remarkable resistance to a wide range of chemical and biological environments. These include biological tissue or fluids as well as strong acids and bases.

Hexagonal Boron Nitride

Learn More

References

- Shtansky, D.V. et al. (2022) Recent progress in Fabrication and application of BN nanostructures and BN-based Nanohybrids, Nanomaterials. 12. doi: 10.3390/nano12162810

- Laturia, A.G. et al. (2018) Dielectric properties of hexagonal boron nitride and transition metal dichalcogenides: from monolayer to bulk. npj 2D Mater Appl. doi:10.1038/s41699-018-0050-x

- Wang, J. et al. (2017) Graphene, hexagonal boron nitride, and their heterostructures: properties and applications. RSC Adv. doi:10.1039/C7RA00260B

Contributors

Written by

Application Scientist

Diagrams by

Graphic Designer