Making Perovskites In Various Glove Box Environments

One of the key challenges in the production of perovskite solar cells (PSCs) lies in maintaining environmental control during manufacturing. Many high-performing PSCs require inert conditions, such as those provided by glove boxes, to prevent degradation from exposure to moisture and oxygen. While these controlled environments ensure high efficiency and stability, they also contribute significantly to research costs and will present a problem with the future scalability of PSCs. As the push for scalable PSCs intensifies, researchers and industry leaders are exploring innovative approaches to simplify manufacturing processes, reduce costs, and enable large-scale production without relying on expensive inert atmospheres. This case study examines how advancements in glove box technology and processing techniques are paving the way for more cost-effective and scalable PSC manufacturing.

The Ossila Glove Box is compact, easy to set up and maintains a good level of inertness. It does this at a significantly lower cost than more complex, more inert systems. However, simpler purge glove boxes cannot maintain as low moisture and oxygen levels as its pricier competitors... but does that matter?

Device Performance vs. Glove Box

The PSC devices in this study were made according to our perovskite solar cells within a glove box guide. It is well documented that working in an inert environment improves the likelihood of creating high efficiency devices. This is often the case for devices that contain organic components, as these are the most sensitive to moisture and oxygen.

Therefore, we use this case study to investigate how inert does an environment need to be for a given process. To do this, we compared the performance of triple-caption perovskite solar cells made in two different processing conditions:

- The Ossila Glove Box maintaining 0.5% O2 content, and <0.75% RH

- A filtration glove box system with less roughly 0.1 ppm levels of O2 and H2O

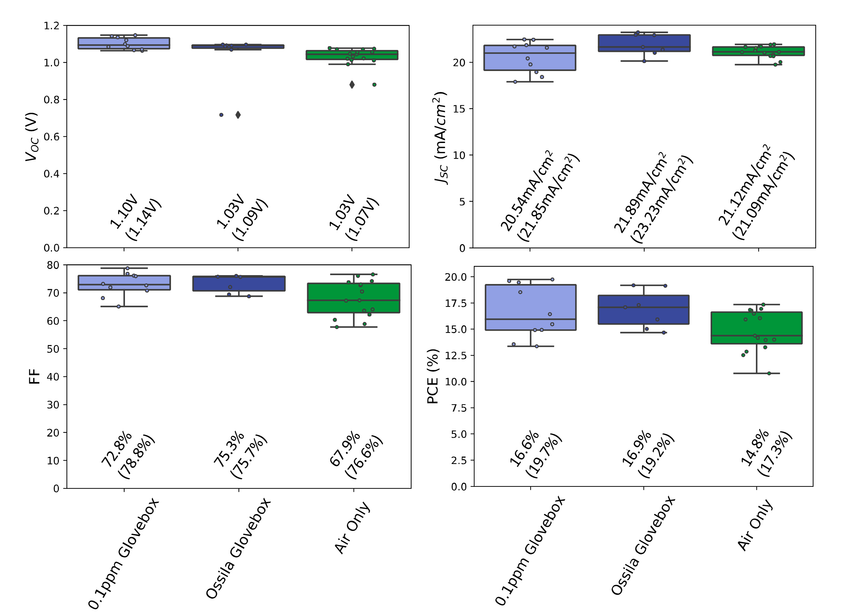

Some perovskite materials are more sensitive to air than others and triple-cation perovskites (CsFAMAPb(Ix Br1-x )3 ) are particularly robust. We therefore also made triple cation devices in air to provide a full comparison. As expected, all three environments made usable perovskite solar cell devices, but with varying power conversion efficiencies (PCEs). Interestingly, we found no significant difference between device made in the Ossila and the filtration glove box.

Our system can maintain an environment with less than 0.5% O2 content and moisture levels as low as 15 ppm, while the filtration glove box can create inert atmospheres O2 and H2O levels of less than 0.1 ppm. Despite this difference in O2 and H2O levels, there is no significant difference between devices.

Devices made in the our glove box have a slightly lower VOC, but an improved JSC compared to those made in the filtration glove box. The devices made in the Ossila Laboratory Glove Box had a champion device efficiency of 19.2%, compared to 19.7% champion for the filtration glove box devices.

This shows that you can fabricate high-performing perovskite solar cells in simpler bench top glove boxes, just as well as in the much more expensive filtration glove box. The levels of >0.5% relative humidity achieved with our glove box are more than suitable for making PSC devices.

Film Quality vs. Glove Box

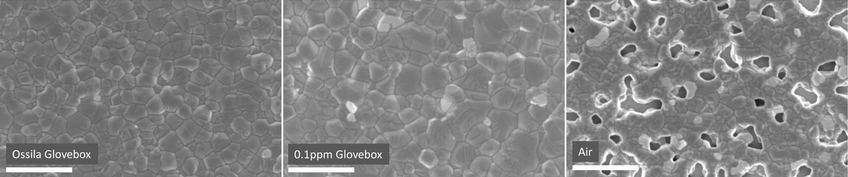

To investigate further, we characterised perovskite thin films prepared in each glove box with scanning electron microscopy (SEM). The perovskite films made in both glove boxes were extremely similar, with the characteristic uniform grains we expect to see. In contrast, those prepared in air have several pinholes and gaps in the film. This explains the reduction in FF, indicating reduction in shunt resistance, hindering device performance. One thing to consider is that this non-uniform structure provides a lot of surface area for moisture and oxygen-related degradation, which may lead to further PCE reduction during stability testing.

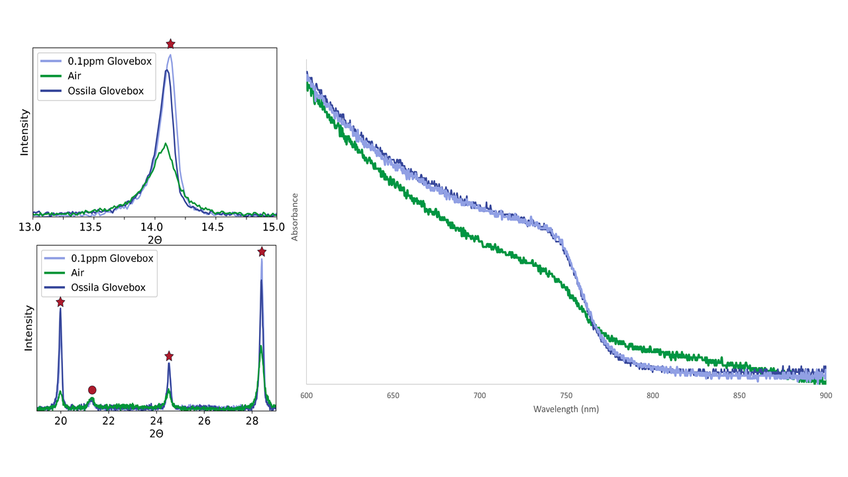

The SEM results agree with the X-Ray Diffraction (XRD) and absorption data shown below. In the XRD data, we can see a strong perovskite peak (e.g. at 14 °) for films made in both glove boxes, suggesting there is very little difference in perovskite crystal orientation for films made in either glove box. As expected, these characteristic peaks are strikingly reduced for the films made in air. Interestingly, this suggests a similar quality of perovskite crystal. The reduction in perovskite peaks seen in the XRD is likely due to the incomplete film layer.

We also show normalised absorption profiles for films made in each atmospheric condition. Again, the films in both glove boxes are almost identical, while the films deposited in air have much lower absorption in the visible region and a tail at higher wavelengths.

Different Perovskites in the Ossila Laboratory Glove Box

To further investigate the suitability of our lab glove box for making PSC devices, we made a range of perovskite solar cells. Below is the best and average PSC devices. We are able to make a number of high efficiency PSC devices in our glove box, including MAPbI3 which are notoriously moisture and air sensitive.

| Perovskite | Average PCE (%) | Best PCE (%) |

|---|---|---|

| Triple Cation Mixed Halide perovskite | 16.4±1.8 | 19.0 |

| MAPbI3 | 17.6±1.1 | 19.3 |

| CsFAPbI3 | 14.0±2.0 | 17.0 |

| I301 | 17.3±1.3 | 19.4 |

These performances rival the performances of those made in the filtration glove box, proving that extremely highly inert conditions are not necessary for making high efficiency perovskite devices.

Glove Box