What is an LTO Battery?

An LTO battery is named after its key component, lithium titanium oxide (LTO) powder. The material is also referred to as lithium titanate with the chemical formula Li4Ti5O12. Unlike most lithium-ion battery materials it is used as the anode active material. LTO anodes are used in electric vehicle batteries and mobile medical devices due to the high level of safety and recharge capabilities.

Advantages of LTO Batteries

LTO is used instead of carbon materials like graphite as the anode active material due to a variety of reasons including:

High Intercalation Potential – Higher lithium intercalation potential of LTO compared to graphite so Li ions are more likely to contribute to the charging and discharging.

Great Rate Capability – 175 mAh g-1 theoretical capacity reached without compromising cycle life and very high rates (800C) reached.

Zero Strain Material – Very little change in volume of the crystal when lithium ions are intercalated and when they are not.

Good Cycle Stability – Zero strain nature increases the amount of time the battery can be charged and discharged, known as their cycle life.

High Li+ Diffusion – Lithium ions can also diffuse through LTO more efficiently than graphite. This means the rates of charge and discharge are much quicker.

Great Safety – with both conventional and low-temperature electrolytes

LTO is compared to other anode materials rather than other lithium based oxides, which are usually used as cathode active materials. The key features of popular anode materials include:

| Anode Material | Density / g cm-3 | Theoretical Specific Capacity / mAh g-1 | Volume Change / % | Cycle Life (cycles) | Full cell energy density / Wh kg-1 | Full cell power density / kW kg-1 |

|---|---|---|---|---|---|---|

| Li4Ti5O12 (LTO) | 3.5 | 175 | 1 | >10,000 | ~100 | 10 |

| Graphite Powder | 2.25 | 372 | 12 | >1000 | ~200 | 5 |

| Silicon Powder | 2.33 | 4200 | 320 | >200 | ~250 | 0.5 |

The high density of LTO is suited to energy storage as more active material can be packed into a given volume compared to other anode materials. The theoretical specific capacity is much lower than other anode materials which is an issue if the battery is used in high-energy-density applications. But the high cycle life and power density are particularly attractive properties for electric vehicle batteries.

Graphite suffers from the growth of lithium dendrites which causes thermal runaway stability issues. LTO anodes do not suffer from the same stability issues even with ultrafast charging.

LTO Crystal Structure and Chemistry

Whilst LTO comes in different crystal phases, the spinel structure is the most commonly used as an anode material. It has the space group Fd3̅m. In this crystal the titanium exists as octahedra coordinated to oxygen atoms with lithium ion in the tetrahedral positions.

Spinel LTO is insulating as there are no free electrons to conduct charge. Within a battery it functions as an anode in a rechargeable system. This is possible as the titanium atoms can undergo redox reactions.

LTO Battery Structure

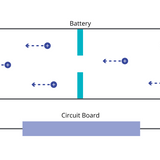

An LTO battery includes an LTO anode, a cathode made from a different lithium based crystal, an electrolyte and a separator.

During the charge and discharge process, LTO undergoes a two-phase transition. In lithium-ion batteries, during the charging process ions move to the cathode and during the discharge process ions move towards the anode. For a battery with an LTO anode the material gains ions during the discharge process. This is possible as LTO can easily exist as two different phases depending on the amount of Li ions present. Starting with the chemical formula Li4Ti5O12 and spinal structure in the charged state, the influx of ions during discharge produces Li7Ti5O12.

Charged State - Li4Ti5O12 - (Li8)8a[Li8/3Ti40/3 ]16d(O32)32e

- Titanium (Ti4+) occupies octahedral 16d sites

- Oxygen (O2-) forms a cubic close-packed (ccp) framework at 32e sites

- Lithium (Li+) occupies the tetrahedral 8a sites

Discharged State - Li7Ti5O12 - (Li16)16c[Li8/3Ti40/3 ]16d(O32)32e

- New lithium (Li+) ions occupy the octahedral 16c site

- Li+ at original 8a site are pushed to the 16c site

- Titanium (Ti4+) gets reduced to Ti3+

- Oxygen (O2-) remains cubic close-packed (ccp) framework at 32e sites

- Forms rock-salt–Li7 (rock salt–LTO)

The movement of lithium ions from the tetrahedral position to the octahedral position happens over the discharge process. As more lithium ions enter the LTO crystal the more likely you are to find lithium ions in the 16c site:

LTO Battery Cathode Materials

For the cathode of LTO batteries, other lithium based crystals are used, including:

- Lithium Iron Phosphate (LFP): Improved power, safety, and cycling stability.

- Lithium Manganese Oxide (LMO): Offers good thermal stability and safety.

- Lithium Nickel Manganese Cobalt: Balances energy density with power output.

Challenges of LTO Batteries

Despite its advantages, lithium titanate (LTO) faces several challenges as an anode material in lithium-ion batteries. These challenges impact its long-term stability, conductivity, and efficiency in various applications.

Electrolyte Reactivity and Electrode Swelling

- LTO reacts with battery electrolytes, particularly at high voltages (~2.4V vs. Li/Li⁺), leading to the formation of an unstable solid electrolyte interphase (SEI).

- This reaction can cause gas generation, leading to battery cell swelling and performance degradation over extended use.

- While LTO is known for its "zero-strain" property, side reactions with the electrolyte can still contribute to the reduction of capacity over time.

Low Electronic and Ionic Conductivity

- LTO has poor electronic conductivity (~10-13 S/cm), making it less efficient at transporting electrons during charge and discharge cycles.

- LTO also has low ionic conductivity (~10-13 – 10-9 cm2/s) which slows down lithium-ion diffusion and can limit high-rate performance in fast-charging applications.

- This is because Ti4+ ions do not have free electrons available for conduction. However, during discharge, as Ti4+ is reduced to Ti3+, localized charge carriers are introduced, allowing electron hopping, which slightly improves conductivity.

Lower Energy Density Compared to Graphite

- While LTO offers superior cycle life and fast charging, its specific capacity (~175 mAh/g) is lower than that of graphite (~372 mAh/g).

- This results in a lower energy density (~70-100 Wh/kg) for LTO-based batteries compared to standard lithium-ion batteries with graphite anodes (~150-250 Wh/kg).

- LTO is less suitable for energy-intensive applications such as consumer electronics and long-range electric vehicles.

Solutions to LTO Challenges

To overcome these limitations, several strategies have been developed to enhance LTO’s conductivity, stability, and overall performance in lithium-ion batteries.

Carbon Coating for Electrolyte Protection

- Coating LTO particles with conductive carbon materials (e.g., graphene, carbon black, carbon nanotubes) helps prevent direct contact between the LTO anode and the electrolyte.

- This reduces unwanted side reactions, suppresses gas formation, and improves overall electronic conductivity.

Nano-Structuring of LTO

- Reducing LTO particle size to the nanometer scale shortens the diffusion path for lithium ions (Li⁺) and electrons, improving charge transport.

- Nano-structured LTO also increases surface area, facilitating faster intercalation and enhancing high-rate capability.

- However, excessive nano-sizing can lead to increased surface reactivity with the electrolyte, requiring surface coatings for stabilization.

Ion Doping for Improved Conductivity

- Doping LTO with foreign ions such as zinc (Zn), vanadium (V), niobium (Nb), magnesium (Mg), or molybdenum (Mo) introduces extra charge carriers, enhancing electronic conductivity.

- Doped ions modify the electronic structure of Ti⁴⁺, allowing better electron hopping and reducing charge transfer resistance.

Incorporation of Conductive Nanomaterials

- Blending LTO with highly conductive nanomaterials, such as carbon nanotubes (CNTs), graphene, or silver nanoparticles, forms a conductive network that enhances electrical connectivity.

- This significantly improves electronic conductivity without compromising LTO’s structural integrity or cycle life.

Battery Materials

Learn More

References

- Li4Ti5O12 spinel anode: Fundamentals and advances in rechargeable..., Zhang, H. et. al., InfoMat (2021)

Further Reading

- Julien, C. M., & Mauger, A. (2024). Fabrication of Li4Ti5O12 (LTO) as Anode Material for Li-Ion Batteries. Micromachines, https://doi.org/10.3390/mi15030310

Contributors

Written by

Application Scientist

Diagrams by

Graphic Designer