What are Multi-Walled Carbon Nanotubes (MWCNTs)?

Multi-walled carbon nanotubes (MWCNT) consist of multiple carbon nanotubes that are nestled within one another. The individual carbon nanotubes are just one atom thick and this gives MWCNTs unique electrical and mechanical properties. It is these properties that make MWCNTs desirable additives in a variety of applications including electronics and vehicle manufacturing.

There are lots of ways in which these one dimensional materials are referred to, including:

- Multi-walled carbon nanotubes

- Multi-wall carbon nanotubes

- Multi-walled nanotubes

- MWCNTs

- MWNT

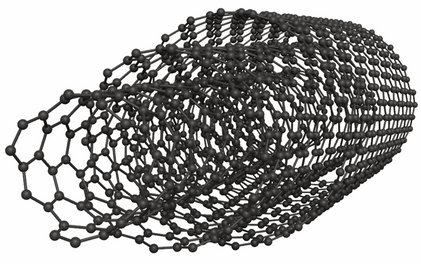

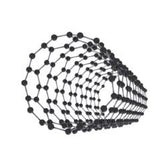

Multi-Walled Carbon Nanotubes Structure

The structure of multi-walled carbon nanotubes consists of cylindrical tubes made of a hexagonal lattice of carbon atoms, similar to that of graphene. The number of nanotubes that are within a MWCNT can vary. There can be as little as 3 layers, to over 20 within one MWCNT. The diameter of both the internal nanotube and the external most nanotube can also vary from 2 nm, to over 50 nm respectively.

There are two structural models that MWCNTs can exist as:

- Russian Doll Model: When a carbon nanotube is nestled inside another it has a smaller diameter than the outer one.

- Parchment Model: A single graphene sheet is rolled up around itself multiple times, similar to parchment or wrapping paper.

Multi-Walled Carbon Nanotubes Properties

MWCNTs exhibit exceptional electrical, thermal, and mechanical properties. These properties are a result of the unique structure and bonding that are features of MWCNTs.

Electrical Conductivity

MWCNT have high electrical conductivity and can impart these properties on other materials when mixed in as a composite. Their high conductivity arises from electron delocalization throughout the tubular structure. All carbon atoms in MWCNTs form strong covalent bonds with three neighboring carbon atoms, leaving a fourth electron in a π-bond. These π-electrons are not localized to a specific atom or bond but are free to move along the length of the tube creating a large π-conjugated system. This system facilitates electron delocalization and as a result charge can be efficiently transported across the structure.

Thermal Conductivity

MWCNT have high thermal conductivity which is a result of the vibrations of the carbon atoms. Most transport of thermal energy is a result of phonon conduction, where thermal energy is carried by atomic vibrations. The strong covalent bonds between carbon atoms and the minimal phonon scattering along the nanotube allow for rapid heat transfer and dissipation.

Mechanical Properties

MWCNT have outstanding mechanical properties as a result of the strength of the carbon-carbon bonds throughout the tubular lattice structure. The multiple layers of nanotubes also adds an extra level of stiffness and makes them less prone to fracture under strain. Whilst MWCNT have a lower tensile strength per-tube than SWCNT, they offer better toughness and reliability. MWCNT are know to improve fatigue life in composites, making them more resistant to the damage caused by cycle loading.

Functionalized Multi-Walled Carbon Nanotubes

The outer walls of MWCNTs can be modified with functional groups such as hydroxides, carboxylic acids, or amides to produce additional functionality. This impacts the chemical and electronic properties of the MWCNTs. After functionalization, the dispersibility and processibility of MWCNTs are often improved. New functional groups can provide binding sites to attach other molecules. This is particularly useful for biological applications where biomolecules can be added to the MWCNT surface to control biological uptake.

Other treatments can also modify material properties such as coating with nickel to add magnetism or graphitization to remove defects.

Examples of functionalized multi-walled carbon nanotubes include:

Multi-Walled Carbon Nanotubes Applications

Applications of MWCNTs have been mainly focused around their use in composites where they can be used as an additive to:

- Improve the mechanical properties of a material

- Improve the electrical properties of a material

Aside from being used as additives, functionalised MWCNTs are being utilised in a variety of medical and biotechnological applications. This is due to their high biocompatibility of carbon nanotubes and the ability to attach specific proteins to functional groups. This can provide a wide variety of targeted therapies such as drug delivery, localised heating for triggering cell death, or even miniature biosensors for in-situ measurements. Here is a brief list of applications of MWCNTs:

- Composite Materials: Used to enhance mechanical strength, electrical conductivity, and thermal properties in polymer, metal, and ceramic composites.

- Electronics: Incorporated in transistors, sensors, and nano-electronic devices due to their excellent electrical conductivity.

- Energy Storage: Applied in batteries and supercapacitors for improved energy density and charge/discharge rates.

- Biomedical Applications: Used in drug delivery systems, biosensors, and tissue engineering for their biocompatibility and ability to carry therapeutic agents.

- Environmental Applications: Utilized in water purification and gas filtration systems due to their high surface area and adsorption capacity.

- Catalysis: Serve as catalyst supports in various chemical reactions, improving efficiency and stability.

- Field Emission Devices: Employed in displays and x-ray tubes due to their excellent field emission properties.

Multi-Walled Carbon Nanotube Production

MWCNTs can be produced in high quantities and are easier to purify (in comparison to single walled and double-walled nanotubes). Chemical vapour deposition with a metal catalyst is the current method used to produce MWCNTs on a large-scale. Hydrocarbon gas is treated at high temperature causing decomposition. Carbon bonds reform under specific cooling conditions to form the MWCNT structures. This technique makes their production costs significantly lower. This is one reason for the adoption of MWCNTs in multiple areas of scientific research.

Multi-Walled Carbon Nanotubes

Learn More

What are Carbon nanotubes?

What are Carbon nanotubes?

Carbon nanotubes (CNTs) have been deemed a wonder material due to their remarkable and highly unique physical and chemical properties. They have received much attention over the past decade as a promising material, particularly in the trending field of nanotechnology.

Learn more... What are Single-Walled Carbon Nanotubes (SWCNT)?

What are Single-Walled Carbon Nanotubes (SWCNT)?

Single-walled carbon nanotubes (SWCNTs) are sheets of graphene that have been rolled up to form a long hollow tube, with wall thickness of a single atom. Their one-dimensional structure gives them extraordinary mechanical, electrical and thermal properties.

Learn more...

References

- Carbon nanotubes: properties, synthesis, purification, and medical applications, Eatemadi, A. et al., Nanomaterials (Basel) (2014)

- Thermal conductivity of carbon nanotube networks: a review, Kumanek, B. et al., J Mater Sci (2019)

- Acid enhanced zipping effect to densify MWCNT packing..., Wang, H. et al., J Mater Sci (2023)

- Dossier on multiwalled carbon nanotubes (MWCNT), OECD Environment (2015)

Contributors

Written by

Application Scientist

Diagrams by

Graphic Designer