ITO Glass Substrates (Unpatterned)

Spectroscopy Equipment, Substrates and FabricationA Range of Unpatterned ITO Glass Substrates

Essential in a wide range of research applications

Transmittance | Characterization | Related Products | Resources and Support

Glass substrates coated with a 100 nm layer of indium tin oxide (ITO). Useful for a variety of experimental techniques including microscopy (STM, conductive AFM), spectroscopy, and electropolymerization.

Specifications

| Substrate Sizes | 20 mm x 15 mm 25 mm x 25 mm 25 mm x 75 mm (microscope slide) |

|---|---|

| Thickness | 1.1 mm |

| Glass Type | Polished soda lime, float glass |

| Substrate Coating | Fully oxidized ITO |

| ITO Thickness | 100 nm |

| ITO Quoted Resistance | 20 Ω.□-1 |

| ITO Measured Resistance* | 14 - 16 Ω.□-1 |

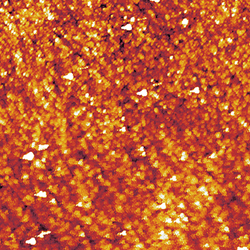

| Glass Roughness | 1 nm RMS (by AFM) |

| ITO Roughness | 1.8 nm RMS (by AFM) |

* Resistances measured using the Ossila Four-Point Probe System.

Please note: We does not offer custom substrate sizes. If you have a product suggestion, please contact us via our feedback page.

Transmittance of ITO Substrates

Characterization

Related Products

The 20x15mm PV/OLED System

The 25x25mm PV/OLED System

The 75x25mm PV/OLED System

Resources and Support

OLED Fabrication Guide

OLED Fabrication Guide

Fabricating OLED devices using Ossila’s pre-patterned ITO substrates is designed to be quick and easy. We've included every detail that we can in this manual so that you can produce efficient devices with as little effort as possible.

Read more... OPV Fabrication Guide

OPV Fabrication Guide

Within this guide, you’ll find comprehensive explanations for each step, along with additional tips and insights we’ve gathered to help you achieve the best possible results.

Read more...