Laminar Flow Hood

Lab Equipment, Life Science Equipment

Type G

Used in the UK, Ireland, Saudi Arabia, Hong Kong, and the UAE.

Type F

Used in the EU (except Ireland), Korea, Russia, Egypt, and mainland China.

Type B

Used in the USA, Canada, Japan, Taiwan, Mexico, and mainland China.

Type I

Used in Australia, New Zealand, and mainland China.

Country not listed? We ship worldwide. Please contact us if you are not sure which plug type you need.

Consistent Air Flow in Benchtop Experiments

Fully equipped with advanced sensor technology, set of filters, stainless steel tray, and UV lighting

Overview | Specifications | Features | Gallery | In the Box | Accessories | Resources and Support

A simple-to-use system, the Ossila Laminar Flow Hood, provides a uniform clean air environment for sensitive samples. The benchtop cabinet is portable and easily fits into your exisiting lab, making it the perfect choice for small-scale experiments.

Designed to be interchangeable, you can switch between a horizontal and vertical configuration to choose the best setup for your experimental needs:

- In the horizontal orientation, achieve clean laminar air flow with minimal turbulence for enhanced sample protection against external contamination.

- The vertical orientation can accommodate bulky equipment and reduces cross contamination between samples that are easily disturbed, like powders.

Standing apart from other systems, laminar flow hoods from Ossila arrive complete with a compatible HEPA filter, pre-filter, sensors, control system, and tray. Plus, the built-in UV light helps to maintain the cleanliness of the work surface.

Uniform Air Flow

510 m3hour-1 with pressure sensors

Interchangeable

Switch between vertical or horizontal

Environmental Sensors

Continuous air quality management

UV Lighting

Guarantee a clean work surface

Specifications

Motor

| Motor Type | Single speed AC blower |

|---|---|

| Maximum Flow Rate | 510m3.hour-1 |

| Noise | 75 dB |

Woven Microfiber Pre-Filter

| Filter Grade | 60% (F5) particle filtration |

|---|---|

| Depth | 10 mm |

High Efficiency Particulate Air Filter

| Filter Grade | 99.99% (H13) particle filtration |

|---|---|

| Pore Size | 0.3 µm |

| Depth | 50 mm |

| ISO Classification | ISO Class 5 |

Particle Sensor

| Sensor Type | Light scattering discrete airborne particulate counter |

|---|---|

| Count Range | 0 particles.m-3 to 100,000 particles.m-3 |

| Count Accuracy | ±10% |

| Particle Size Bins | 0.3 µm – 1 µm 1 µm – 2.5 µm 2.5 µm – 5 µm 5 µm – 10 µm |

Differential Pressure Sensor

| Sensor Type | MEMS barometric pressure sensor |

|---|---|

| Pressure Range | 30,000 Pa – 120,000 Pa |

| Accuracy | ±6 Pa |

| Resolution | ±0.2 Pa |

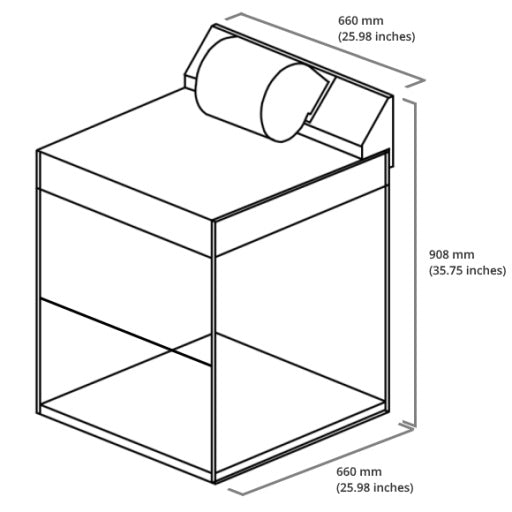

Dimensions and Weight

Vertical Orientation

| Internal Area | 590 mm x 630 mm (23.2" x 24.8") |

|---|---|

| Internal Height | 570 mm (22.4") |

| Weight | 24 kg |

Horizontal Orientation

| Internal Area | 590 mm x 630 mm (23.23" x 24.80") |

|---|---|

| Internal Height | 580 mm (22.83") |

| Weight | 25.85 kg |

Materials and Finish

| Plenum and Back Panels | 1.5 mm Aluminium, textured black powder coating |

|---|---|

| Clear Side Panels and Sash | 5 mm acrylic, transparent with polished edges |

| Working Surface Tray | 1.5 mm stainless steel, #4 brushed finish |

Additional Specifications

UV Light

| Type | High efficiency UV LED |

|---|---|

| Wavelength | 280 nm (UVC) |

| Intensity | 26 mW |

| Power Saving Feature | Automatic UV light off |

| Timer | 10, 15, 30 minutes, and indefinite |

White Light

| Type | High efficiency LED array |

|---|---|

| Brightness | 850 Lumens |

System

| Display Type | 24 bit colour TFT LCD display |

|---|---|

| Display Resolution | 480 x 272 px |

| Display Size | 4.3" |

| Interface | Tactile keypad |

| Power Supply | IEC C13 power cable |

| Voltage Range | 220 V – 240 V |

| Fuse | 1 A |

Please note: Countries with 110V mains will require a step up transformer rated for powers up to at least 250W to operate the equipment.

Certification and Standards

| UK Conformity Assessment (UKCA) |

Low Voltage Electrical Equipment Electromagnetic Compatibility Restriction of Hazardous Substances |

|---|---|

| Conformitè Europëenne (CE) Mark |

Low Voltage Directive (2014/35/EU) Electromagnetic Compatibility (EMC) (2014/30/EU) Restriction of Hazardous Substances (RoHS) (2011/65/EU + 2015/863) |

| International Standards | BS EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control, and laboratory use. General requirements. |

Laminar Flow Hood Features

High Purity Air

The H13 grade HEPA filters capture over 99.99% of all airborne particulates. High air purity is easily achieved and maintained, with ISO classifications as low as ISO Class 5, using our smart air sensing technology.

Smart Air Sensing Technology

A range of sensors monitor air quality and pressure to provide live updates about the environment and filter saturation. The smart technology allows the motor to operate at an optimal speed, alert you to upcoming filter changes, and warn you if the air flow changes.

Low Operating Costs

Equipped with low energy lighting, infrared motion sensors for running in standby mode, UV LED with variable timer settings, and back pressure sensing to monitor HEPA filter saturation. Together, these features keep energy usage to a minimum and reduce operating costs.

Fully Equipped and Flexible

Unlike other manufacturers, our laminar flow hood is equipped with all the useful components as standard—there are no hidden costs or charges before you have a working system. Plus, our interchangeable design means you no longer need to decide between a horizontal or vertical setup.

Laminar Flow Hood Gallery

Horizontal Orientation

Vertical Orientation

In the Box

- Flat-pack laminar flow hood with interchangeable configuration

- HEPA filter

- Pre-filter

- Stainless steel tray

Accessories and Related Products

Resources and Support

Vertical vs Horizontal Laminar Flow Hood

Vertical vs Horizontal Laminar Flow Hood

The difference between a vertical and horizontal laminar flow hood is the direction of air flow through the workspace.

Read more... Getting Started with the Laminar Flow Hood

Getting Started with the Laminar Flow Hood

This short video guide shows you how to get started with your new equipment. It is easy to control the fan, lighting, and internal UV light.

Read more...