Getting Started With a Laboratory Syringe Pump

A syringe pump is an indispensable tool for accurately controlling the delivery of fluids. They are used in a wide range of applications, from chemical and biological research to medical and industrial settings. These versatile devices are used for tasks such as reagent addition, sample injection, continuous infusion, and more. Understanding the fundamentals of syringe pumps is essential for their effective use, maintenance, and troubleshooting.

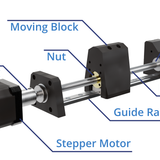

At its most basic level, a syringe pump consists of a motor-driven linear actuator that precisely controls the movement of a syringe plunger, allowing for the controlled dispensing or withdrawal of fluids. The pump's electronics and software work together to regulate the motor's speed and direction, enabling users to set specific flow rates and volumes with high accuracy and reproducibility.

Syringe pumps can operate in two different modes these are:

- Infusion: Infusion involves pushing fluids into a system, such as in the case of delivering a nutrient solution to cell cultures.

- Withdrawal: Involves drawing fluids out, which is essential for applications like sampling the blood from a patient or animal over time.

- Infusion/Withdrawal: Is when the pump can both push solution and withdraw it, and these are particularly valuable when the application requires a fluid to be precisely added and removed in sequence.

Laboratory Syringe Pump Dispensing Process

-

To use a syringe pump effectively, start by select an appropriate syringe based on several factors, including the required volume, flow rate, and chemical compatibility.

Syringes come in various materials, such as glass, plastic, or stainless steel, and in different sizes, ranging from microliters to milliliters.

-

After selecting the appropriate syringe, load it into the pump and make sure the plunger is securely attached. You can then sets the desired flow rate, volume, and direction using the pump's interface or software. This may involve entering values directly, selecting from preset programs, or creating custom flow profiles.

How to attach syringe to Single Syringe Pump Some advanced syringe pumps (such as the Ossila Dual Syringe Pump) offer features like programmable multi-step methods, auto-fill, and auto-refill, . These can streamline workflows, saving time and improving repeatability.

-

Once started, the linear actuator precisely controls the movement of the syringe plunger, dispensing or withdrawing fluid at the programmed rate.

The pump's electronics continuously monitor and adjust the motor's speed to maintain the set flow rate, ensuring consistent and accurate fluid delivery.

Users can monitor the progress of the pumping operation through the pump's display or software interface, providing real-time information on the delivered volume, elapsed time, and remaining volume.

Using a Syringe Pump in a Laboratory

Common issues that can affect the performance of syringe pumps include leaks, air bubbles, and syringe plunger stiction.

- Leaks can occur due to worn or damaged seals, loose connections, or incompatible syringe materials.

- Air bubbles in the syringe or tubing can cause inconsistent flow rates and inaccurate volume delivery.

- Plunger stiction, which refers to the jerky motion of the plunger due to friction or contamination, can lead to irregular flow and reduced accuracy.

Promptly addressing these issues through proper maintenance, troubleshooting, and timely repairs is essential for ensuring reliable performance. This maintenance processes include:

- Regular cleaning of the pump components, including the syringe, plunger, and tubing to prevent contamination and buildup of residues.

- Periodic lubrication of the pump's moving parts, such as the lead screw and guide rods, reduces friction and wear, to ensure smooth operation.

- Calibration is another essential maintenance task, which involves verifying and adjusting the pump's performance to maintain accurate flow rates and volume delivery.

Syringe Pump

Learn More

How To Use and Set Up the Ossila Syringe Pump

How To Use and Set Up the Ossila Syringe Pump

With no external dependencies, both the Ossila Single Syringe Pump and Ossila Dual Syringe Pump are quick and easy to set up and use

Read more... How Do Syringe Pumps Work?

How Do Syringe Pumps Work?

Syringe pumps are electromechanical devices that are designed to convert rotational motion into linear motion

Read more...We used pre-trained AI to help us write this page. As part of our editorial process, our in-house experts review, fact-check, and edit all AI-generated content to make sure we provide you with accurate and helpful information.