Getting Started with the Ossila Slot Die Coater

Although slot die coating is an extremely powerful technique, it is primarily considered to be an industrial method. As such, most slot die coaters are designed to cater to industry rather than academia, and even relatively simple systems come at a high price. These systems are often larger and more complex than what is required by researchers who are just starting to develop the processing techniques required for depositing thin films.

The Ossila Slot Die Coater gives researchers access to a slot die coating, enabling them to optimise ink formulation and processing parameters without the need for large print runs. Ultimately, this helps ensure that their findings can be scaled-up for real-life applications and makes slot die coater ideal for pilot-level production and scale-up process feasibility tests.

What is Slot Die Coating?

Compatible with both roll-to-roll and sheet-to-sheet deposition processes, slot die coating is one of the best techniques available for scalable thin film deposition. It gives highly accurate film uniformity, has a wide processing window, and is an extremely reliable method for wet thin film coating. The theory behind slot die coating is very straight-forward; as a pre-metered technique, control of thickness is simply governed by the solution flow rate and substrate speed.

The most important part of any slot die coating machine is the head, which features a narrow slot through which the solution flows. The rate of flow is precisely controlled to ensure an even coating. The Ossila Slot Die Coater uses a syringe pump to do this and is capable of producing coatings with variations lower than 5% across large areas and a variation of 0.05% over 100mm. The wide processing window ensures stable defect-free deposition for various solution viscosities, and the presence of any coating defects can be eliminated by varying several geometric parameters, which do not themselves alter the coating thickness.

Controlling Film Thickness

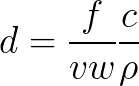

As slot die coating is a pre-metered coating technique, the thickness of the deposited wet film only depends on the solution flow rate, the speed of the substrate, and the width of coating. When the solution concentration and material density is taken into account it is possible to determine the dry film thickness, this is given in the equation below.

Defect-Free Coating

Slot die coating relies upon the formation of a stable coating bead. This bead consists of an upstream and downstream meniscus, which needs to be pinned to the lip of the slot die head. By balancing the flow from the slot die head against the viscous flow on the substrate surface, this bead can be stabilised. Various parameters can be changed to alter these two competing flows - this includes the solution flow rate, substrate speed, head height, solution wetting, and slot die head channel thickness. This allows for multiple ways to get the coating process into the stable coating window to obtain defect-free films.

Slot Die Coating Applications

Slot die coating is the gold standard for scalable thin film processing. The method is commonly used in manufacturing, and can achieve high coating speeds with excellent accuracy and very little solution waste. The Ossila Slot Die Coater brings this to your lab.

There are a significant number of applications for slot die coating, including:

- Organic Photovoltaics

- Organic Field-Effect Transistors

- Conductive Polymers

- Nanowires and Nanotubes

- 2D Materials

- Organic and Perovskite Light-Emitting Diodes

- Perovskite Photovoltaics

- Electrolytes and electrodes for Li-ion batteries

- Dye-Sensitized Solar Cells

Slot Die Coater