HEPA Filter: What Is It and How Does It Work?

HEPA filters, alongside ULPA filters, belong to a category of mechanical filters. The acronym HEPA stands for high efficiency particulate air, and these filters boast an exceptional ability to achieve a high standard of particle filtration. They are specially designed to effectively separate and remove physical particles from a moving stream of gas. In a laminar flow hood, they create a contaminant-free environment.

Composed of many randomly arranged fibers, made of materials such as polypropylene, polyester or fiberglass, the diameter between fibers is less than one micron apart. Particles of various sizes are filtered out, through different mechanisms, by the mesh formed by the fibers. The fundamental principle is that air or gas flow can navigate around any barrier material, but the particles will be intercepted and absorbed.

HEPA filters often contain several layers of filter material held in between pleated separator structures. Filtration material is woven between separator plates to increase the surface area of the filter material, while the separators keep layers from touching. This layered structure means that there is a constant thickness of filter material that the gas must travel through before it escapes the filter.

As air or other gases travel through this fibrous structure, particles are removed via several different mechanisms. These filtration mechanisms include:

- Direct impact and absorption

- Interception

- Indirect diffusion

- Electrostatic attraction

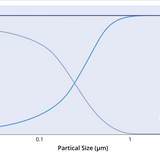

The effectiveness of various particle filtration methods varies depending on the size of the particles they target.

Inertial Impact Filtration

Inertial impact will filter out the largest size particles using a fairly simple phenomenon. Large particles within a moving stream of gas will have a good amount of inertia. Due to this, these bigger contaminants cannot change direction easily. As the air streamlines are diverted around filtration material, these larger particles will continue in the same direction. Unable to divert around the fibers, the particles are trapped by the filter.

These large particles tend to be the first to be absorbed by the filter material as they often follow a relatively straight line of travel. They will be absorbed within the first few layers of the filter material and remain there.

Interception Filtration

Particles that are small enough can be carried along air flow streamlines. If the streamline changes direction, the particles will also change direction. In this case when air flow is interrupted by the filter material, both the streamlines and the particles can flow around the obstruction. Most of these particles will be a sufficient distance away from the filtration material to pass without collision. However, some of these particles are close enough that they encounter the filter material as they pass around it. These particles will become captured, this is known as interception filtration.

As these particles pass through the layers of filter material, the probability that they will be intercepted increases. As the size of the particle decreases, the probability of capture through this method also decreases. Particles need to be close enough to the filter material for interception to occur.

Diffuse Filtration

As the particle size further decreases, there is another change in the motion of the particles. The particles no longer flow within streamlines. Small particles begin to exhibit Brownian motion. Brownian motion refers to the erratic movement of particles due to the impact of other individual atoms on that particle. This causes the particles to move in a motion known as ‘random walk’. Particles below 3 µm in size will exhibit this effect — it becomes extremely pronounced in particles where d>0.1 µm. This motion allows particles to cross streamlines. The overall movement of the particles still tends to follow the flow of air but the path they take becomes more chaotic, and significantly longer.

The random motion means that the particle is likely to impact upon the surface of the filter, becoming embedded within it. The filtration of these ‘smallest’ particles benefits from a longer time spent within the filter material. The effectiveness of diffuse filtration can be improved by ensuring a deep enough filter material and a slow enough air flow speed.

Electrostatic Attraction

The fibrous material of HEPA filters has a slight electrostatic charge. Very small particles with an electrostatic charge will be attracted to the filtration material due to electrostatic attraction. Small charged particles are drawn out of the streamline to be imbedded in the filter. This further increases the ability of these filters to remove extremely small particles.

These filters are exceptionally effective at removing particles from gas streams, using various mechanisms for different particle sizes. Equipped with HEPA filters, the Ossila Laminar Flow Hood ensures the highest standard of particle removal, making them essential for maintaining clean workspace environments.

Laminar Flow Hood

Learn More

HEPA Filter Size Chart

HEPA Filter Size Chart

High Efficiency Particulate Air (HEPA) filters are designed to efficiently remove airborne particles and contaminants, making them indispensable tools in laboratories and cleanroom facilities.

Read more... ULPA vs HEPA Filters: Which One is Right for You?

ULPA vs HEPA Filters: Which One is Right for You?

Ultra-Low Particulate Air (ULPA) and High-Efficiency Particulate Air (HEPA) filters are both used in laminar flow hoods to remove particles from incoming air.

Read more...Contributing Authors

Written by

Product Developer

Application Scientist