How to Choose a Linear Stage

With many manufacturers offering expansive ranges with little supporting information, finding the right linear stage can be a daunting task. Yet, choosing a positioning system can be important for the success and efficiency of your application.

Based on your research needs, there are key factors to consider when selecting a linear stage.

Features to Consider

Accuracy and Precision

Achieving the right accuracy and precision is crucial and can impact the quality and reliability of your data. Slight deviations or inaccuracies can lead to compromised experimental outcomes.

Before choosing a linear stage, you should determine your required level of precision. Our linear stages achieve micrometer-level positioning and we have two levels of precision to choose from. A C7 ball screw is used in our standard precision stages, while a C5 ball screw is used in our high precision stages to reduce positioning error values.

It is useful to consider the repeatability of the stage, which measures its ability to return to the same position consistently. High repeatability is essential for applications demanding reliability.

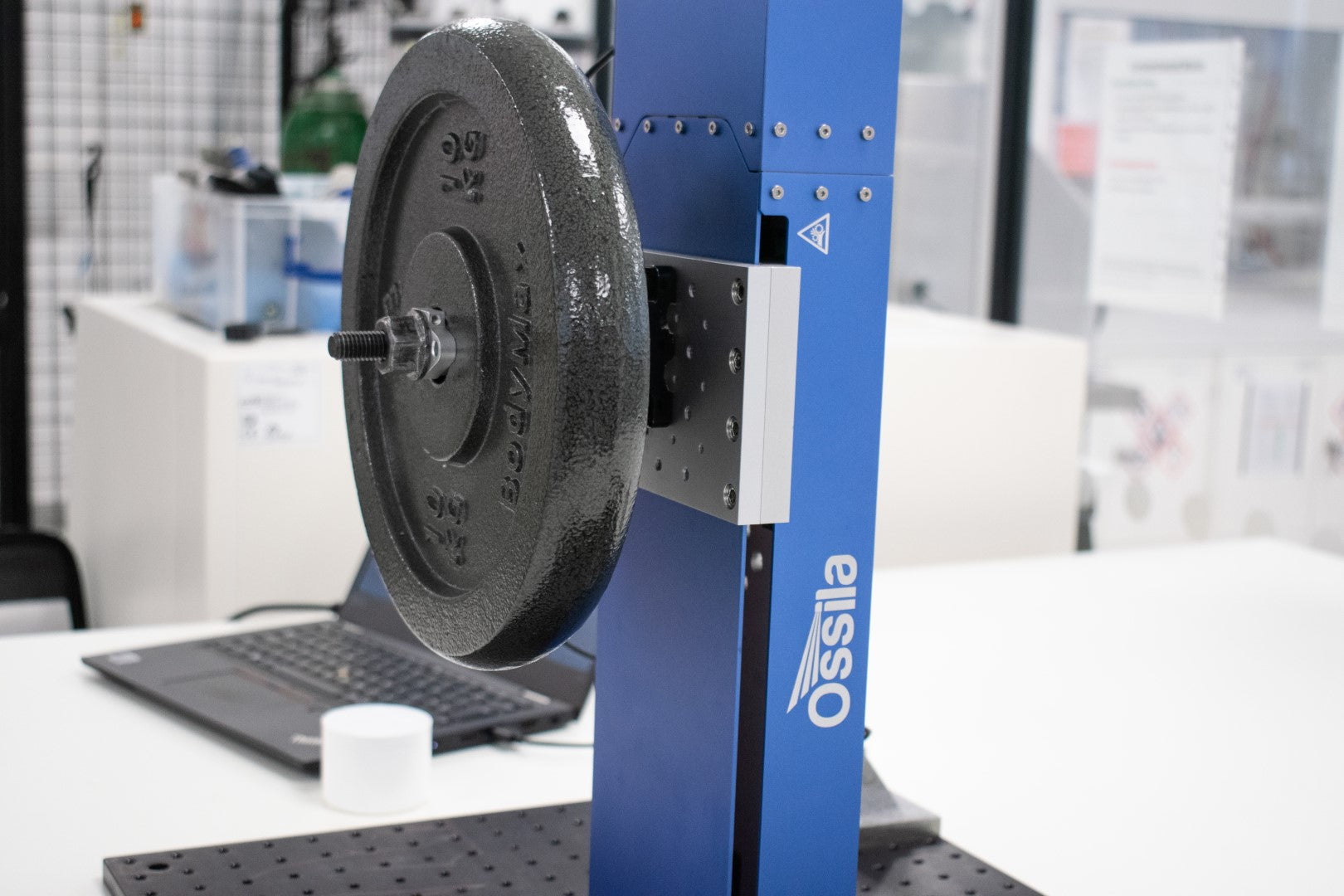

Load Capacity

Linear stages come with different load capacities. Evaluate the weight and size of the components you need to move. It is crucial to choose a stage that can handle the weight requirements of your specific application. Larger and heavier linear stages typically have more robust constructions which results in higher load capacities. Overloading a stage can result in poor performance, calibration errors, and mechanical damage.

If you want to combine stages to create an XY or XYZ stage, each stage will need to support the weight of the other stages in addition to your apparatus. Choosing a linear stage with a greater load capacity than you need is a good way to future proof your equipment.

Many of our linear stages have a horizontal load capacity of 30 kg and vertical load capacity of 10 kg, while our compact range has a horizontal capacity of 10 kg and vertical capacity of 3 kg.

Travel Range

Our linear stages are available with varying travel distances, from 50 mm to 200 mm. Select a stage that can accommodate the required travel range without any limitations or restrictions.

For most benchtop applications, you will likely need either a 100 mm or 200 mm linear stage. Larger scale applications probably require a long travel linear stage to achieve the desired distance. For both, considering the potential of future scalability can reduce the need to purchase additional equipment.

Modularity

While some multi-axis systems are integrated, our linear stages benefit from a modular design. This allows you to combine any two or three models to create a multi-axis system when you need it.

With our XYZ systems, they can be assembled or used individually to implement precise positioning into an array of positioning tasks, regardless of motion requirements.

More Considerations

Workspace Constraints

Our linear stages are available in different sizes, from compact benchtop models to long travel systems. Consider the available space in your lab and whether the linear stage can fit comfortably within those constraints.

Budget and Value for Money

Linear stages vary in cost, depending on their precision, load capacity, and features. It is essential to find a balance between performance and cost.

Determine the features and specifications that are critical for your application and explore our range of stages to find a system that fits within your budget.

Support and Service

Good support can be essential in resolving any issues or questions that may arise during installation, operation, or maintenance.

We offer reliable technical support, warranty options, and free resources to help you make the most of your new equipment.

Choosing a Linear Stage

Choosing the right linear stage requires a thorough assessment of your application and the specific requirements, and an evaluation of your available options.

Balancing factors like precision, load capacity, environmental conditions, and cost will help you select a linear stage that meets your current needs and ensures efficiency and reliability for future applications.

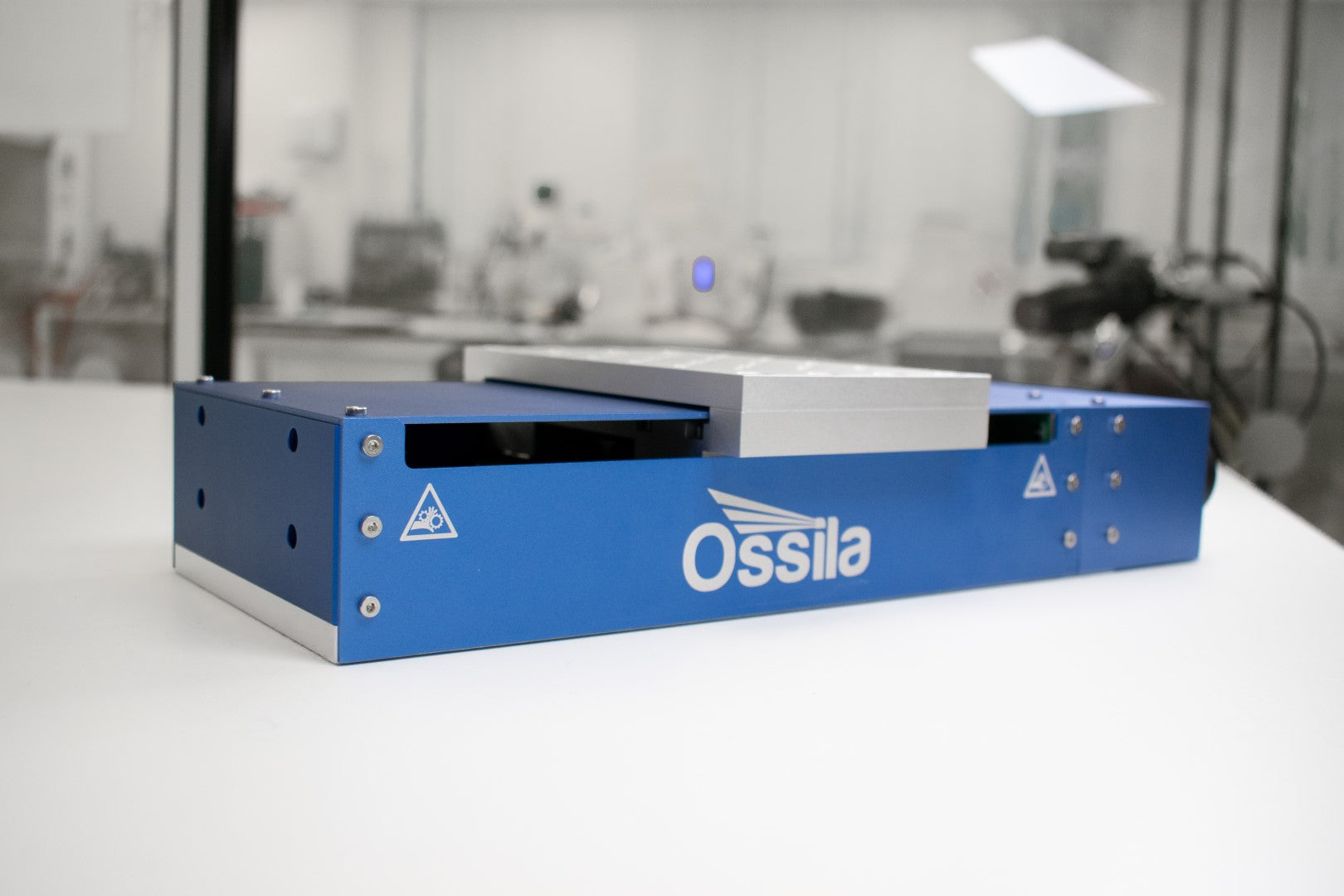

We offer a range of high quality linear stages to meet the diverse needs of a range of applications. Our stages are built with precision, durability, and ease of use in mind, ensuring consistent and reliable performance.

Linear Stage

Contributors

Written by

Editor and Writer

Reviewed by

Application Scientist

We used pre-trained AI to help us write this page. As part of our editorial process, our in-house experts review, fact-check, and edit all AI-generated content to make sure we provide you with accurate and helpful information.