ULPA vs HEPA Filters: Which One is Right for You?

Ultra-low particulate air (ULPA) and high-efficiency particulate air (HEPA) filters are used in laminar flow hoods to remove particles from the workspace air. Both of the filters do this to a high standard, creating a contaminant-free environment. Yet, there are some key differences that may impact your decision when choosing which filter you need.

Filtration Methods

Both ULPA and HEPA filters use a dense mesh of fibrous material to trap particles carried by air streams. Each apply the same filtration mechanisms to achieve this:

- Inertial impaction - Particles are physically intercepted by the fibers of the filter.

- Interception - Particles are carried by the airstream around fibers, but still interact with them.

- Diffusion - Particles diffuse through the air and are not as affected by the air streamline. These are eventually trapped by the fibers of the filters.

ULPA filters have a denser mesh of fibers than HEPA filters, allowing them to trap smaller particles.

Filtration Efficiency

HEPA filters will remove 99.995% of their most penetrating particles . Whereas ULPA filters remove 99.999% of their most penetrating particles.

While both filters are highly efficient, ULPA filters offer slightly increased protection against particles contamination. HEPA filters can help you maintain an ISO Class 5 Standard Cleanroom. ULPA can help you create an ISO Class 3 Standard Environment.

Most Penetrating Particle Size

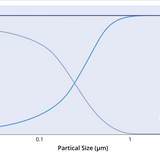

The most penetrating particle size (MPPS) represents the particle size that is most able to pass through a filter. Filters are always tested for their efficiency against this particle size to guarantee minimum filtration quality. The efficiency of HEPA or ULPA filters is higher for particles that are both larger and smaller than the most penetrating particle size.

The MPPS of a filter depends on the material and type. ULPA filters have an MPPS of 0.12 micrometers, while HEPA filters have an MPPS of 0.3 micrometers. This means that ULPA filters are more effective at removing smaller particles than HEPA filters.

Achievable Air Speed

HEPA filters can achieve a higher air speed than ULPA filters as their internal mesh is less dense. This means that ULPA filters require more power to move air through a given space. Therefore, air circulation systems that use a ULPA filter have higher power consumption and slightly increased running costs.

Cost

ULPA filters are more expensive than HEPA filters. This is because they are more difficult to manufacture and require more material to create a denser mesh.

Additionally, ULPA filters have a shorter lifetime than HEPA filters. This will increase the time and money you need to invest in replacing and maintaining filters in your clean environment.

Choosing the Right Filter

ULPA filters are more effective at removing smaller particles than HEPA filters. However, they are also more expensive, have a shorter lifetime, and have a lower achievable air flow.

Here are some additional things to consider when choosing between ULPA and HEPA filters:

- The size of the particles you need to remove

- The air flow requirements of the application

- The budget you have available

- The level of maintenance you are willing to do

ULPA Filters

ULPA filters can be used in various applications where the highest level of particle filtration is required, such as:

- Microelectronics manufacturing

- Medical laboratories

HEPA Filters

HEPA filters can be used in a wider variety of applications, including:

- In clean rooms (achieving up to ISO Class 5 standard)

- Semiconductor research

- R&D laboratories

- Media preparation, growing cell cultures and for DNA experiments

Laminar Flow Hood

Learn More

HEPA Filter: What Is It and How Does It Work?

HEPA Filter: What Is It and How Does It Work?

The acronym HEPA stands for High Efficiency Particulate Air, and these filters boast an exceptional ability to achieve a high standard of particle filtration.

Read more... HEPA Filter Size Chart

HEPA Filter Size Chart

High Efficiency Particulate Air (HEPA) filters are designed to efficiently remove airborne particles and contaminants, making them indispensable tools in laboratories and cleanroom facilities.

Read more...