What is a Probe Station? Design, Types & Applications

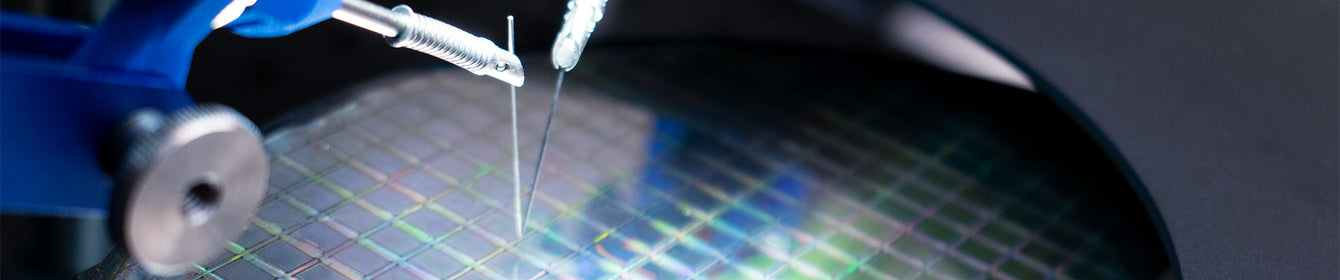

As devices shrink to microscopic scales, the ability to accurately measure and characterize their electrical properties becomes increasingly challenging. A probe station is a specialized tool designed to help conduct precise electrical measurements on small devices or sensitive materials. It allows engineers, researchers, and technicians to probe, test, and characterize the electrical properties of organic semiconductors, wafers, microchips, MEMS devices, and other small-scale electronic components. The main benefit of probe stations is they allow you to position testing probes with a high level of accuracy, repeatability, and stability to avoid damaging your sample.

At its core, a probe station consists of several key components, which work together with measurement instruments to analyze electrical parameters, enabling highly accurate testing.

Fine-Tipped Probes

Fine-tipped probes are used to make electrical contact with your sample. These are usually made of conductors like tungsten, beryllium/copper alloy, or nickel. Specialized probes are also available to meet specific testing requirements.

Micromanipulators

Most probe stations use several micromanipulators to position these electrodes or probes with high spatial resolution. One each for a source-sink measurement, or a handful for more complicated semiconductor measurements. Their required resolution will depend on the desired application. For example, the Ossila Micromanipulator can achieve a positioning accuracy of 10 microns along three rectilinear axes.

Optical Microscope

An optical microscope will provide visual feedback to aid in positioning both the sample and probes. Long working distance objectives give greater flexibility and movement of the probes.

Base Station or Stage

The stage-mounted chuck serves as the foundation for the substrate and provides greater flexibility in positioning of the probes in relation to the desired probe points.

These components work together with measurement instruments to analyze electrical parameters, enabling highly accurate testing.

Probe Station Applications

Probe stations are integral in fields like semiconductor manufacturing, electronics research, telecommunications, and automotive and aerospace industries.

Device Characterization

Probe stations are essential for wafer-level testing in fields like semiconductor manufacturing. Before a wafer is diced into individual chips, it undergoes testing to assess the performance of each die. This early-stage testing helps manufacturers identify faulty dies, reducing waste and improving overall production efficiency.

Wafer-Level Testing

Probe stations are also used to measure a wide range of electrical parameters, including DC characteristics like current-voltage (I-V) curves and capacitance-voltage (C-V) curves, as well as RF characteristics such as S-parameters. By analysing these measurements, engineers can gain insights into the device's performance, reliability, and suitability for specific applications.

Failure Analysis

When a device malfunctions, a probe station can be used to pinpoint the root cause of the failure. By systematically probing different parts of the device, engineers can identify defective components or faulty connections. This information is crucial for improving future designs and manufacturing processes.

Research and Development (R&D)

In R&D environments, probe stations are used to test new materials, device structures, and fabrication processes. Researchers can use them to explore the electrical properties of novel materials like organic semiconductors, 2D materials, and nanostructures.

Optoelectronic Testing Stations

In addition to electrical testing, probe stations can be used to test optoelectronic devices, such as photodiodes, LEDs, and laser diodes. By integrating optical sources and detectors into the setup, engineers can measure the performance of devices that interact with light, which is crucial for applications in fibre optics, solar cells, and display technologies.

Life Sciences

These instruments are also crucial in electrophysiology, where they are used to position microelectrodes with extreme precision to record electrical activity from individual neurons or muscle cells. This allows researchers to study ion channel behaviour, synaptic transmission, and neural circuitry in real-time. In cell biology, micromanipulators are used for various tasks, such as injecting biological molecules into cells, performing patch-clamp experiments, or isolating specific cells for further analysis. They are also employed in genetic engineering for microinjection of DNA or RNA into embryos or cells, and in microdissection to manipulate or dissect small tissue samples under a microscope.

Specialized Probe Stations

Beyond basic setups, specialized probe stations are available for advanced testing techniques:

- RF Probe Stations and Microwave Probe Stations: These systems are designed for high-frequency testing of devices like amplifiers, oscillators, and antennas. Special RF probes and equipment are used to measure parameters like S-parameters and impedance at high frequencies, making probe stations essential for the development of 5G technology and other high-speed communication systems.

- Microscale & Nanoscale Probe Stations: With the increasing miniaturization of electronic components, probe stations can be equipped with micromanipulators that allow for precise positioning of probes on very small features, such as micron-sized or nanometre-sized structures. This is essential for testing MEMS (Micro-Electro-Mechanical Systems) devices, nanowires, and other small-scale components. These systems require high precision micromanipulators and high resolution microscopes.

- Cryogenic & Temperature-Dependent Probe Stations: Some probe stations come with thermal chucks that allow testing at different temperatures. This is important for understanding how devices perform under various thermal conditions, such as in high-temperature or cryogenic environments. Temperature-dependent testing is particularly useful for automotive electronics and space applications, where devices must operate reliably under extreme conditions.

- Vacuum Probe Stations: Some probe stations are designed to operate in vacuum chambers or controlled atmospheres (e.g., within a glove box) to test devices that are sensitive to air or moisture. This is particularly important for testing organic semiconductors, such as non-fullerene acceptors, 2D materials, and other delicate structures that may degrade when exposed to the environment.

Set Up Your Probe Station

A probe station is a specialized tool designed for simple and precise electronics testing. Ossila’s Micromanipulators and Source Measure Unit are designed to integrate seamlessly into probe station setups, offering the precision and versatility required for a range of applications.

The Ossila Micromanipulator is designed to enable high precision probing in any laboratory. The key features include:

- Precise XYZ axes control

- 10 μm axis resolution

- Maximum travel length of 10 mm

- Magnetic base for easy probe station integration and coarse manoeuvrability

- Compact and versatile design

- Low leakage current for sensitive semiconductor measurements

- Compatible with our other measurement equipment including the Source Measure Unit

Micromanipulator

Learn More

Micromanipulator Drift and Other Common Errors

Micromanipulator Drift and Other Common Errors

The performance of a micromanipulator can suffer from various mechanical issues, including drift, backlash, side play, and sticking. Understand these issues and how our engineers have implemented solid design principles to avoid potential movement issues from the start.

Read more...Contributors

Written by

Product Developer

Diagrams by

Graphic Designer