Which UV Ozone Cleaner Features Do I Need?

UV ozone cleaners from other manufacturers can come with an array of additional features. More features can often be mistaken for a more effective performance. However, it is always important to assess the necessity and applicability of additional features in your experimental set up. There are even instances where thes features have little to no advantage, even in more complex applications.

The Ossila UV Ozone Cleaner is built with simplicity and efficacy in mind. We offer a model that works effectively without unnecessary, complicated, or confusing features.

Heated Stage

Over 150°C, the higher the temperature of the material, the faster the reaction rate of UV Ozone cleaning. Therefore, the temperature of the substrate being cleaned can be manipulated to encourage faster cleaning rates. To do this, some systems integrate a heated sample stage into a UV ozone cleaner.

Advantages

This feature is important when users are trying to remove thick layers of contamination from the surface, such as residual photoresists. A heated stage can reach temperatures up to, and sometimes beyond, 150°C.

Disadvantages

The integration of heated stages can present some challenges:

- Heated stages can easily cause the temperatures of the lamp to exceed the optimal temperature window. This reduces the lifetime of the lamp and light output.

- Designing a system that can maintain an optimal lamp temperature while heating the stage is costly. It requires the use of quartz windows to allow physical separation and active cooling of the lamps.

- Increasing the temperature increases the rate of ozone breakdown as well as the target reaction rate.

Do You Need a Heated Stage?

The addition of a heating element to the UV ozone system may not be worth the additional costs. This is likely the case if you only require the removal of thin monolayers of material, or are only interested in surface modification—in this case, our system is ideal.

If you are removing thicker layers of material, the heating element is likely a necessity to ensure reasonable cleaning times.

Ozone Filtration and Extraction

UV ozone cleaners can be fitted with in-built filtration. The ozone is absorbed by a filter before the air is extracted from the system and vented into the laboratory.

Advantages

Significant amounts of ozone are generated as part of the cleaning process, and even small quantities can be hazardous to users. Built-in filtration increases user safety as ozone does not need to be exhausted using external equipment.

Disadvantages

With the addition of filtration to the system, there is a duty to perform more regular maintenance to maintain safety standards. The filter must be replaced, and the integrity of the seals checked regularly. Ozone can severely damage the gaskets used to create airtight seals, increasing maintenance costs. It also increases the downtime of the system as maintenance is carried out.

Do You Need Integrated Filtration?

Extraction, filtration, and exhausting of the ozone can be done simply by operating the Ossila UV Ozone Cleaner within a fume hood. Both an extraction or recirculation fume hood will provide the required protection from ozone.

Gas Inlet

Adding a gas inlet port to the sample chamber allows you to add oxygen to the chamber from an external source. Some UV ozone cleaners available on the market have inlet ports designed for this purpose, allowing the user to connect an oxygen source directly to the system.

Advantages

With more oxygen present in the atmosphere, the probability of the UV light from the lamp being absorbed is increased. This increases the amount of oxygen radicals present for the formation of ozone and reactions with organic materials on the samples surface. This improves the cleaning rate.

Disadvantages

Increases to the oxygen content of air can dramatically increase the flammability of materials used, and the risk and severity of potential fires. Even a small increase in oxygen can change the behaviour of normally inflammable materials. The increased risk produced by working within an oxygen enriched environments means significant care must be taken.

UV ozone cleaners that allow for the input of oxygen must meet more stringent design regulations. The complexity of the design to ensure the system is safe for operation in explosive environments, can lead to more expensive systems.

Do You Need a Gas Inlet?

While increasing oxygen levels can improve the cleaning rate of a system, you must be able to safely operate it. This requires a set up that can handle a high oxygen environment and experiment. Additionally, the experiments you plan to run must be safe to undertake in these conditions.

The risk involved with high oxygen environments may sometimes outweigh the benefits of a higher cleaning rate. Therefore, simpler and safer to operate systems, like our UV ozone cleaner, can be a better fit for lab set up not equipped for high oxygen environments.

Sample Distance

The intensity of light at the surface of a sample has an impact on the cleaning rates. From this, it is often assumed that decreasing the distance between the light and the sample, increases the intensity of light. To implement this theory, some UV ozone cleaners have adjustable sample trays.

However, this theory assumes that the light source is acting as a point light source (similar to a single bulb). The intensity of a point light source will drop off with r2 and the light is given off equally in all directions. For most UV ozone systems, the light is generated by a series of lamps or a grid lamp, which acts as a plane light source. While there is some drop off in intensity with plane light sources, it is not as drastic as with point light sources.

As the distance between the sample and lamp increases, the drop off in intensity measured is minimal. Therefore, the adjustment of distance has little impact on the intensity at the surface of the sample.

Do You Need Adjustable Sample Distance?

The implementation of sample height adjustment is not needed in UV ozone cleaners. Reducing the distance can result in significant reductions in uniformity across the surface of the sample. We implement a fixed distance into the UV ozone cleaner, which is optimised to provide maximum uniformity while maintaining a high intensity at critical wavelengths.

Choosing a UV Ozone Cleaner

When selecting a UV ozone cleaner, it is essential to consider the specific requirements of your laboratory setup and the nature of the materials you are cleaning. Features such as heated stages, ozone filtration and extraction, gas inlets, and adjustable sample distances offer potential benefits but also come with their own set of challenges and disadvantages.

The Ossila UV Ozone Cleaner prioritizes simplicity and efficiency, ensuring effective cleaning without the complications and costs associated with additional, often unnecessary features. Ultimately, the choice should be guided by the balance between the desired cleaning efficiency and the practicality, safety, and cost-effectiveness of the equipment in your specific experimental environment.

UV Ozone Cleaner

Learn More

UV Ozone Cleaning: Theory and Application

UV Ozone Cleaning: Theory and Application

UV ozone cleaning relies upon the use of a high-intensity UV light source, which illuminates the surface to be cleaned with two specific wavelengths of light. Low pressure mercury vapour discharge lamps are typically used, like the synthetic quartz UV grid lamp in the Ossila UV Ozone Cleaner, which have two dominant emission peaks at 184 nm and 254 nm.

Read more... Surface Energy: Formula & Definition

Surface Energy: Formula & Definition

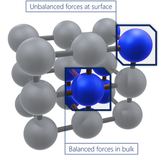

Surface free energy is a measure of the excess energy present at the surface of a material, in comparison to at its bulk. It can be used to describe wetting and adhesion between materials, but is not often used quantitatively.

Read more...