Cobalt(II) Phthalocyanine, CoPc

CAS Number 3317-67-7

Charge Transport Layer Materials, High Purity Sublimed Materials, Hole Injection Layer Materials, Materials, OLED Materials, Semiconducting MoleculesCobalt Phthalocyanine, p-type semiconducting material used in organic electronic devices

HIL material used to improve turn-on voltage and luminance in OLEDs, Cobalt phthalocyanine (CoPc), CAS No. 3317-67-7, Sublimed ≥99.0%

Cobalt phthalocynine (CoPc), a member of metal phthalocyanines (MPcs), is frequently used in many organic electronic devices such as light-emitting diodes (LEDs), organic photovoltaics (OPVs), organic field-effect transistors (OFETs) and chemical sensors as a p-type semiconducting material. Compared to other hole-injection layer (HIL) materials, most metal phthalocyanines are water and air stable, thermally stable, and nontoxic. They can be sublimed or sputtered with highly uniform, thin films on a variety of substrates. The synthesis of such materials are also relatively inexpensive and easy to prepare. The chemical structure of MPc allows tuning of its ionisation potential or HOMO levels by altering the central atom in Pc macrocycles.

Using cobalt phthalocyanine (CoPc) layer as a hole-injection layer (HIL), remarkable improvements in turn-on voltage and luminance have been observed in organic light-emitting diodes (OLED) [1, 2, 3, 4]. The driving voltages of the MPc electroluminance devices are found to decrease in the order of ZnPc < CuPc < FePc < CoPc < PbPc < NiPc < VOPc < SnPc < H2Pc. This is in agreement with the order of HOMO levels of MPcs [1].

General Information

| CAS number | 3317-67-7 |

|---|---|

| Chemical formula | C32H16CoN8 |

| Molecular weight | 571.46 g/mol |

| HOMO/LUMO | HOMO 5.0 eV, LUMO 3.4 eV [1] |

| Synonyms |

|

| Classification / Family | Phthalocyanine salt, Hole-injection layer (HIL) materials, Light-Emitting Diodes, Organic electronics. |

Product Details

| Purity | Sublimed ≥99.0% |

|---|---|

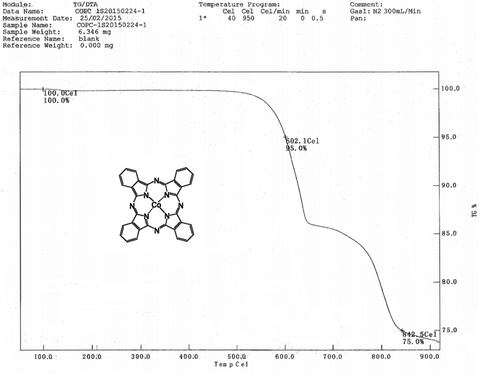

| Thermal Gravimetric Analysis | 602.1 °C (5% weight loss) |

| Colour | Purple powder |

*Sublimation is a technique used to obtain ultra pure-grade chemicals. For more details about sublimation, please refer to the Sublimed Materials.

Chemical Structure

Device Structure(s)

| Device structure | ITO/CoPc (10 nm)/NPB (60 nm)/Alq3 (75 nm)/LiF (1 nm)/Al (200 nm) [2] |

|---|---|

| Colour | Green |

| Turn-on Voltage at1 cd/m2 | 4.3 V |

| Max. Luminance | 53,700 cd/m2 (14.8 V) |

| Power Efficiency at 100 mA/cm2 | 1.02 lm W−1 |

| Device structure | ITO/NPB (30 nm)/CBP:8 wt% (t-bt)2Ir(acac)* (15 nm)/BPhen(35 nm)/LiF (1 nm)/CoPc:C60 (4:1) (5 nm)/MoO3(5 nm)/NPB(30 nm)/CBP:8 wt% (t-bt)2Ir(acac)* (15 nm)/BPhen (35 nm)/Mg:Ag (100 nm) [3] |

|---|---|

| Colour | Yellow |

| Max. EQE | 16.78% |

| Max. Luminance | 42,236 cd/m2 |

| Max. Current Efficiency | 50.2 cd/A |

| Max. Power Efficiency | 12.9 lm W−1 |

*For chemical structure information, please refer to the cited references

Characterisation (TGA)

MSDS Documentation

Literature and Reviews

- A relationship between driving voltage and the highest occupied molecular orbital level of hole-transporting metallophthalocyanine layer for organic electroluminescence devices, L. Zhu et al., Thin Solid Films 396, 213–218 (2001). doi:10.1016/S0040-6090(01)01232-9.

- Improved efficiency of organic light-emitting diodes using CoPc buffer layer, P-C. Kao et al., Thin Solid Films 498, 249– 253 (2006). doi:10.1016/j.tsf.2005.07.120.

- Effect of bulk and planar heterojunctions based charge generation layers on the performance of tandem organic light-emitting diodes, Z. Ma et al., Org. Electronics, 30, 136-142 (2016). doi:10.1016/j.orgel.2015.12.020

CoPc MSDS sheet

CoPc MSDS sheet