Perovskite Precursor Ink for Air Processing

Materials, Perovskite Inks, Perovskite MaterialsPerovskite precursor ink for the fabrication of solar cells to achieve high PCE values

High quality ink with the ability to be processed in an ambient environment

Overview | Specifications | Device Performance | Resources and Support

I101 perovskite ink has been specially formulated in the Ossila laboratories to be deposited by spin coating. Our I101 perovskite ink is designed for air processing in low-humidity environments. Using a mixture of methyl ammonium iodide (MAI) and lead chloride (PbCl2) dissolved in dimethyl formamide, our I101 perovskite ink will convert to a methylammonium lead halide perovskite under heat. The final product is a methylammonium lead iodide perovskite with trace amounts of chlorine given by the formula CH3NH3PbI3-xClx.

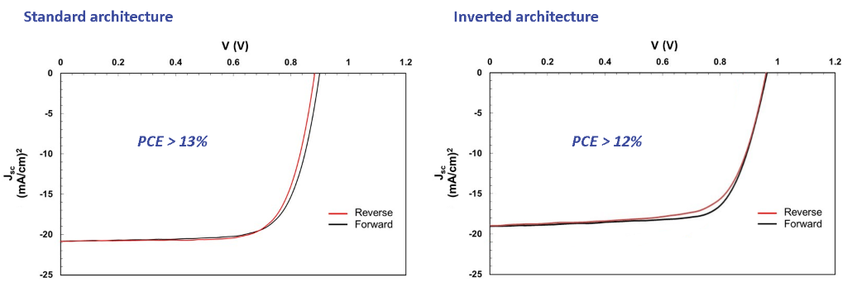

The main use of CH3NH3PbI3-xClx is in the fabrication of solar cells, our I101 ink can be used in both standard and inverted architectures; and can achieve power conversion efficiency (PCE) values of over 13% (see our device performance section for more information).

Using our I101 recipe provided, 5ml of solution is capable of processing up to 160 substrates (1,280 devices using our 8-pixel substrate design).

Specifications

| Perovskite Type | CH3NH3PbI3-xClx |

|---|---|

| Precursor Materials | Methyl Ammonium Iodide (99.9%), Lead Chloride (99.999%) |

| Precursor Ratio | 3:1 |

| Solvent | Dimethyl Formamide (99.8%) |

| Optical Bandgap | 1.56 – 1.59 eV |

| Energy Levels | Valence Band Minimum 5.4 eV, Conduction Band Minimum 3.9 eV |

| Emission Peak | 770 – 780 nm (PL); 755 – 770 nm (EL) |

| Standard Architecture PCE | 13.7% Peak; 13.0% ±0.25% Average |

| Inverted Architecture PCE | 13.1% Peak; 11.9% ±0.50% Average |

| Processing Conditions | Air processing; low humidity (20% to 35%) |

| Packaging | 10 x 0.5 ml sealed amber vials; 3 x 10 ml sealed amber vials |

I101 Device Performance

Below is information on photovoltaic devices fabricated using our standard architecture and inverted architecture recipes for I101 inks. All scans were taken after 10 minutes under illumination of an AM1.5 source, using a voltage sweep from -1.2 V to 1.2 V then from 1.2 V to -1.2 V at a rate of 0.2 V.s-1; no bias soaking was performed on devices.

| Architecture | Standard | Inverted | ||

|---|---|---|---|---|

| Sweep Direction | Forward | Reverse | Forward | Reverse |

| Power Conversion Efficiency (%) | 13.5 | 13.7 | 12.4 | 13.1 |

| Short Circuit Current (mA.cm-2) | -20.8 | -20.8 | -18.8 | -18.8 |

| Open Circuit Voltage (V) | 0.88 | 0.90 | 0.96 | 0.96 |

| Fill Factor (%) | 73 | 73 | 69 | 72 |

References

Perovskite Photovoltaics

The single biggest application of perovskite materials is for photovoltaic devices.

- Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. J. Snaith et. al. Science. 338 (2012) 643-647 DOI: 10.1126/science.1228604

- Additive enhanced crystallization of solution-processed perovskite for highly efficient planar- heterojunction solar cells. K-Y. Jen et. al. Adv. Mater. 26 (2014) 3748-3754 DOI: 10.1002/adma.201400231

- Morphological control for high performance, solution-processed planar heterojunction perovskite solar cells. J. Snaith et. al. 24 (2014) 151-157 DOI: 10.1002/adfm.201302090

Perovskite LED and Lasing

Due to the high photoluminescence quantum yield of perovskites at room temperature, the application of these materials in light-emitting diodes (LEDs) is of great interest.

- Bright light-emitting diodes based on organometal halide perovskite. R. H. Friend et. al. Nature Nanotechnology, 9 (2014) 687-692 doi:10.1038/nnano.2014.149

- Interfacial control towards efficient and low-voltage perovskite light-emitting diodes. Hang et. al. Adv. Mater. 27 (2015) 2311-2316 DOI: 10.1002/adma.201405217

- High photoluminescence efficiency and optically pumped lasing in solution-processed mixed halide perovskite semiconductors. H. Friend et. al. J. Phys. Chem. Lett. 5 (2014)1421-1426 DOI: 10.1021/jz5005285

Scale-Up Processing

Due to the ability to process perovskites based upon MAI:PbCl precursors in air, the material opens up the possibility of applications in large-scale deposition techniques.

- Upscaling of perovskite solar cells: Fully ambient roll processing of flexible perovskite solar cells with printed back electrodes. C. Krebs et. al. Adv. Energy Mater. 5 (2015) 1500569 DOI: 10.1002/aenm.201500569

- Highly efficient, felixble, indium-free perovskite solar cells employing metallic substrates, M. Watson et. al. J. Mater. Chem. A, 3 (2015) 9141-9145 DOI: 10.1039/C5TA01755F

- Efficient planar heterojunction mixed-halide perovskite solar cells deposited via spray-deposition. G. Lidzey et. al. Energy Environ. Sci. 7 (2014) 2944-2950 DOI: 10.1039/C4EE01546K