What is Graphene Oxide?

Graphene oxide (GO) is oxygen-functionalized graphene. It is a 2D material with a hexagonal lattice of carbon atoms, derived from oxidized graphite. GO has unique properties including easy dispersion in polar solvents and tunable electrical and optical features. GO is now commercially available and can be further modified for a wide range of applications, from optoelectronics to water purification. For these reasons, GO opens up new possibilities in material science and nanotechnology, promising revolutionary advances across various industries.

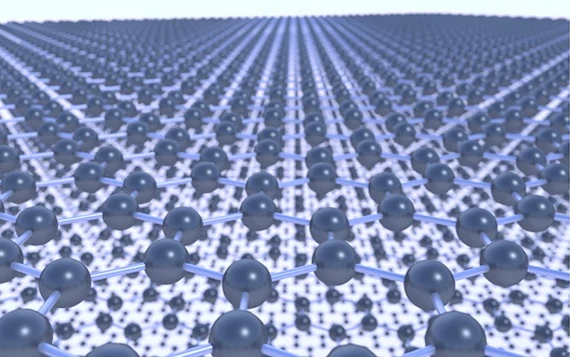

Graphene Oxide Structure

The structure of 2D graphene oxide (GO) is similar to that of graphene. It is a single layer of 3D graphite oxide (or graphitic oxide) - just like 2D graphene is a single layer of 3D graphite. Graphite oxide is produced by treating graphite with oxidizers and acids. This process results in the oxygen-containing functional groups:

- Epoxy groups (C-O-C)

- Hydroxy groups (-OH)

- Carboxylic acid groups (-COOH)

These groups appear randomly on the GO layers. As a result, GO contains carbon, oxygen, and hydrogen in variable ratios. The ratio of carbon and oxygen helps you determine the extent to which the oxidation was successful.

The structure and properties of graphene oxide are dependent on its synthesis method and the degree of oxidation. GO maintains a similar layered structure to graphite, but the spacing between layers is almost two times larger (~0.7 nm). This increased spacing is due to the polar nature of the functional groups, which cause a repulsive force between the layers. The space between layers of graphite oxide can be changed by varying the amount of oxygen-containing functional groups and the amount of water the material is exposed to.

You can access a single or a few layers of graphene oxide via the delamination/exfoliation of graphite oxide. This can be done in a number of ways, such as increasing the pH of graphite oxide in solution or by sonicating it. These methods can be much more gentle than the techniques used to access graphene therefore the GO layers are less damaged. The atomically thin, 2D nature of graphene oxide means it has a much larger surface area compared to layered graphite oxide.

Graphene Oxide Synthesis

Hummers' method is one of the most widely used chemical processes for synthesizing graphene oxide (GO) from graphite. It involves the oxidation of graphite using a mixture of strong acids and oxidizing agents, leading to the exfoliation of graphite into graphene oxide sheets. Here's an outline of the process:

Materials:

- Graphite powder: The starting material, typically natural or synthetic graphite.

- Potassium permanganate (KMnO₄): A strong oxidizing agent used to oxidize the graphite.

- Concentrated sulfuric acid (H₂SO₄): Provides an acidic environment to facilitate the oxidation.

- Sodium nitrate (NaNO₃): Used to aid the oxidation process (optional in some variations).

- Hydrogen peroxide (H₂O₂): Used to quench the reaction and reduce residual permanganate.

Procedure:

- Preparation: Graphite powder is first mixed with sodium nitrate and concentrated sulfuric acid. This creates a highly acidic medium necessary for the oxidation.

- Oxidation: While maintaining the solution at low temperatures (typically 0°C), potassium permanganate is gradually added to the mixture. The temperature is kept low to prevent excessive heat from accelerating the reaction too quickly. The addition of KMnO₄ oxidizes the graphite, causing oxygen-containing functional groups (like hydroxyl, epoxide, and carboxyl groups) to attach to the graphite layers.

- Increase in Temperature: After the slow addition of potassium permanganate, the temperature is slowly increased to about 35–50°C. This aids the further oxidation of graphite and the separation of layers, forming graphite oxide.

- Dilution: The reaction mixture is carefully diluted with water. The addition of water can lead to an exothermic reaction, so it is done slowly to prevent the temperature from rising too quickly.

- Quenching: To stop the reaction and remove excess oxidizing agents, hydrogen peroxide (H₂O₂) is added to the mixture. This reduces residual permanganate and manganese-containing byproducts, turning the solution into a yellowish or brownish color, indicating the formation of graphene oxide.

- Purification: The product is washed repeatedly with water, and sometimes hydrochloric acid (HCl), to remove sulfate ions, metal ions, and other impurities. The washing process is typically followed by filtration and centrifugation.

Properties of Graphene Oxide

The polar functional groups of graphene oxide give it distinct properties compared to other 2D materials (especially graphene). Some of the key properties:

| Property | Graphene Oxide (GO) Characteristics |

|---|---|

| Chemical Reactivity | Highly reactive due to oxygen functional groups |

| Electrical Conductivity | Poor (insulating or semi-conductive); conductivity increases with reduction (rGO) |

| Thermal Conductivity | Lower than pristine graphene due to disrupted sp² bonding |

| Mechanical Strength | Strong, but less so than graphene; flexible and elastic |

| Optical Properties | Transparent and good UV absorption |

| Hydrophilicity | Highly hydrophilic and dispersible in water and polar solvents |

| Surface Area | High surface area |

| Magnetic Properties | Paramagnetic behavior due to structural defects |

| Biocompatibility | Biocompatible in some contexts, though toxicity requires further investigation |

Tunable Properties

You can dynamically tune the performance of graphene oxide as an electrical insulator by varying the number of oxygen-containing groups. Random oxidation on the graphene oxide sheets disrupts the sp2 bonding networks and π-conjugation. This interrupts the flow of electrons and reduces conductivity. To increase conductivity, you can remove oxygen containing functional groups by chemical or physical reduction reactions. This reinstalls the delocalized hexagonal lattice structure. As GO is easily dispersed in solvent, you can perform these reactions in solution. This results in potentially monodispersed graphene or reduced graphene oxide particles.

The optical properties of graphene oxide are linked to its electronic properties. Therefore, you can also tune the optical properties of graphene oxide by varying the amount of oxygen containing functional groups.

Processing Methods for Graphene Oxide

Graphene oxide is easily dispersed within water and other polar organic solutions due to its polar functional groups. You can therefore process GO at higher concentrations than graphene (up to 5 mg.ml-1). This has opened it up for use in solution process-based applications such as optical coatings, transparent conductors, thin-film batteries, chemical resistant coatings, water purification, and many more. Some of those solution based processing methods include:

- Spray Coating: Applies GO onto surfaces using spray coating for uniform thin films in applications like sensors or coatings.

- Dip Coating: Submerges a substrate into a GO solution and pulls it out to create a thin GO layer on the substrate.

- Electrophoretic Deposition (EPD): Applies an electric field to a GO suspension to deposit GO onto a charged substrate.

- Spin Coating: Spins a substrate while applying a GO solution to create a uniform thin film.

- Printing Methods: Utilizes inkjet, screen printing, or 3D printing to apply GO in specific patterns for flexible electronics or sensors.

Functionalized Graphene Oxide

You can functionalize graphene oxide further, adding polymers, nanoparticles, biomolecules, metals, fluorescent compounds and much more (Yadav et al., 2022). Further functionalisation can occur both covalently (physical attachment) and non-covalently (adsorbed). This means you can introduce a whole host of surface chemistries, which allows you to tailer GO for a given application. These applications include optoelectronics, drug delivery, chemical sensors, membrane filtration, flexible electronics, solar cells and more.

| Functionalization | Application | Resulting Properties |

| PEGylation | Tissue Engineering | Biocompatible |

| Antibodies | Biosensing, Drug Delivery | Analyte selectivity |

| Fluorophore | Biomedical Imaging, Drug Delivery | Fluorescence |

| Gold Nanoparticles | Biosensing | Different electrochemical properties, catalyst |

| Metal Oxide Nanoparticle | Chemical Sensing | Different electrochemical properties, catalyst |

| Titanium Oxide | Membrane Filtration | Photocatalyst |

Graphene Oxide Powder

Learn More

Graphene vs Graphite

Graphene vs Graphite

Graphene is a single layer of carbon atoms arranged in a hexagonal pattern, like a sheet of paper. Graphite, on the other hand, is made up of many layers of graphene stacked on top of each other, like a stack of paper.

Read more... Safely Reducing Graphene Oxide

Safely Reducing Graphene Oxide

The conversion of graphene oxide back to graphene is therefore of huge interest to both the scientific and industrial community.

Read more...References

- Aliyev, E. et al. (2019). Structural Characterization of Graphene Oxide: Surface Functional Groups and Fractionated Oxidative Debris, Nanomaterials (Basel), 9(8), doi: 10.3390/nano9081180

- Yadav, S. et al. (2022). An Update on Graphene Oxide: Applications and Toxicity, ACS Omega, 7(40), doi: 10.1021/acsomega.2c03171